Factors Affecting Drying Time

Super glue, or cyanoacrylate adhesive, is renowned for its rapid bonding capabilities. Understanding the factors influencing its drying time is crucial for achieving optimal results in various applications. These factors range from environmental conditions to application techniques and the properties of the glue itself.

Environmental Influences

Several environmental conditions significantly impact the drying time of super glue. Temperature and humidity are key players in this process. Higher temperatures generally accelerate the drying process, as increased kinetic energy promotes faster chemical reactions. Conversely, lower temperatures slow down the drying time. Similarly, higher humidity levels can hinder the drying process by increasing the moisture content in the air, competing with the glue for evaporation. This moisture interferes with the drying mechanism, leading to slower and sometimes uneven drying.

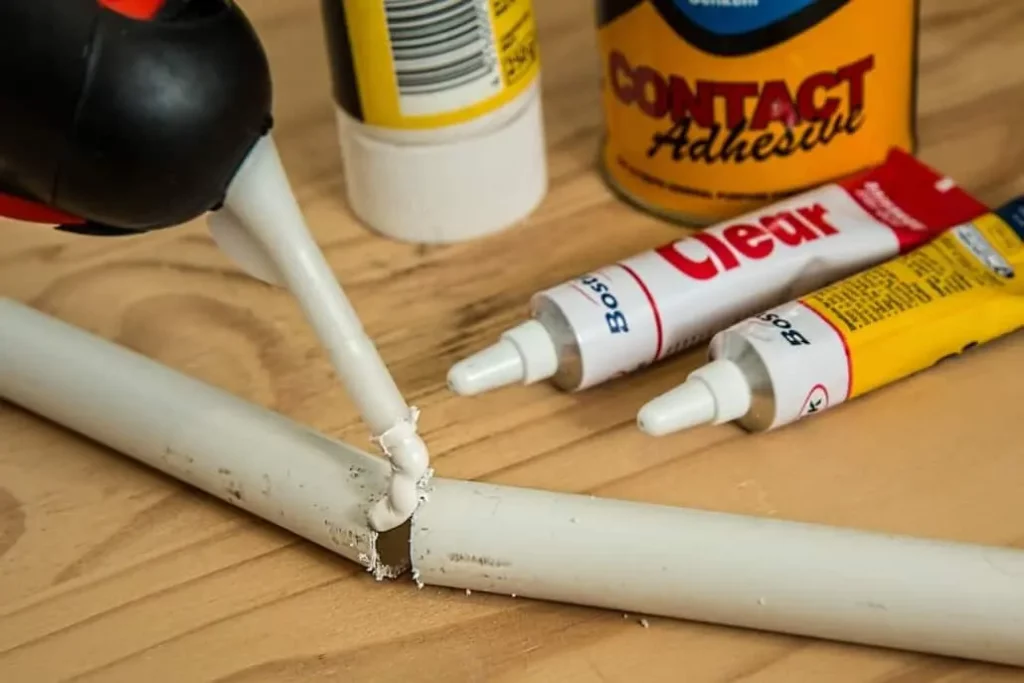

Application Techniques

The method of applying super glue directly influences the drying time. A controlled, precise application, such as using a small amount of glue on a toothpick or applicator, results in a thinner layer, accelerating the evaporation process. Conversely, applying a thick layer of glue spreads the adhesive over a larger surface area, leading to a longer drying time. The glue’s contact with the air is critical. For instance, applying glue in a confined space, or under a covering, can limit air circulation, slowing down the drying time.

Surface Area and Glue Thickness

The surface area to which the glue is applied plays a significant role in drying time. A larger surface area necessitates a larger quantity of glue, resulting in a thicker application and a longer drying time. Conversely, a smaller surface area allows for a thinner application, reducing the drying time. Thickness of the glue layer is also critical. A thicker layer requires more time for the solvent to evaporate, resulting in a slower drying time. This is especially evident when applying super glue to large surfaces or creating complex joints.

Glue Type Variations

Different types of super glue, varying in their formulation, have distinct drying times. This difference stems from the specific chemical composition of the cyanoacrylate resin. Some formulas are designed for rapid bonding, while others are engineered for specific applications requiring slower, more controlled drying times.

Table of Drying Times

| Glue Type | Temperature (°C) | Humidity (%) | Drying Time (seconds/minutes) |

|---|---|---|---|

| Standard Cyanoacrylate | 25 | 50 | 5-10 seconds |

| Standard Cyanoacrylate | 25 | 80 | 10-20 seconds |

| Standard Cyanoacrylate | 10 | 50 | 20-30 seconds |

| High-Strength Cyanoacrylate | 25 | 50 | 10-15 seconds |

| High-Strength Cyanoacrylate | 10 | 80 | 20-30 seconds |

Note: These are estimated values; actual drying times can vary based on specific conditions and application techniques.

Measuring Drying Time

Accurately determining the drying time of super glue is crucial for various applications, from crafting projects to industrial repairs. Understanding the factors influencing drying time is important, but precise measurement techniques are essential for repeatable results and consistent quality. Precise timing allows for better project planning and reduces the risk of errors due to premature or delayed bonding.

Methods for Measuring Drying Time

Precise measurement of super glue drying time involves employing standardized methods. These methods ensure reliability and accuracy, allowing for reproducible results. Several techniques are available, each with its own advantages and limitations.

Detailed Procedure for Drying Time Experiments

A standardized procedure is essential for reliable and comparable results. A controlled environment is critical to minimize external factors influencing the drying process. This procedure ensures consistency in the results.

- Preparation: Ensure the super glue is a consistent brand and type. Prepare a clean, flat surface for application. Use a consistent application method (e.g., a small, controlled drop). Maintain a constant temperature and humidity throughout the experiment. Record the specific brand, type, and batch number of the super glue being tested.

- Application: Apply a uniform amount of super glue to the designated area, as per the application guidelines. Document the application method, noting the size and shape of the applied drop. Carefully record the time of application.

- Measurement: Use a precise timer or stopwatch to accurately record the time taken for the glue to reach the desired state of dryness. Clearly define the criteria for “dry” (e.g., no longer tacky to the touch, able to support a light weight). Note the specific conditions at the time of the measurement.

- Data Recording: Thoroughly record all the data, including the time of application, the time at which the glue reaches the designated dry state, the ambient temperature and humidity, and any other relevant observations. This will allow for analysis of the data and identification of patterns.

Materials Needed for an Experiment

A comprehensive list of materials is crucial for successful and reliable drying time experiments. The specific materials may vary based on the desired level of precision.

- Super glue (specified brand and type).

- Timer or stopwatch with a precision of at least one second.

- Clean, flat surface (e.g., a piece of glass or metal).

- Ruler or caliper for precise application measurements.

- Pencil and notepad for recording data.

- Thermometer and hygrometer for environmental monitoring.

- A variety of weights, ranging from light to medium weight, to test the bonding strength.

- Gloves to protect hands.

- A controlled environment, like a climate-controlled laboratory, if possible.

Common Errors and Solutions

Inaccurate measurements often stem from overlooking specific aspects of the experimental setup. Understanding these potential errors and their solutions ensures accurate results.

- Inconsistent application method: Use a consistent application method (e.g., a small, controlled drop) to ensure that the glue is applied in the same manner each time. This prevents variability in the drying process.

- Ignoring environmental factors: Constant temperature and humidity are essential for accurate results. A controlled environment helps eliminate the impact of fluctuating conditions. Measure and record temperature and humidity during the experiment.

- Vague definition of “dry”: Define the criteria for “dry” (e.g., no longer tacky to the touch, able to support a light weight) to ensure uniformity in the measurement process. This will prevent subjectivity in determining the end point of drying.

- Insufficient trials: Conduct multiple trials with different application methods, sizes, and weights to ensure consistency and reliability. This will help identify any outliers and provide a more accurate average drying time.

Tools and Techniques for Measuring Drying Time

This table Artikels various tools and techniques used in measuring super glue drying time, highlighting their advantages and disadvantages.

| Tool/Technique | Procedure | Accuracy | Advantages/Disadvantages |

|---|---|---|---|

| Stopwatch | Record the time from application to the defined dry state. | High, if precise stopwatch is used. | Simple, widely available. Requires consistent observation. |

| Digital Timer | Use a digital timer for precise timekeeping. | Very High. | Highly accurate, minimizes human error. May require specialized software for data analysis. |

| Visual Inspection | Observe the glue’s appearance and tackiness. | Low to Moderate. | Easy to perform. Subjective and less accurate than objective methods. |

| Weight Test | Apply a known weight to the glued area and record the time until it holds. | Moderate to High, depending on the precision of the weight. | Demonstrates bonding strength. Requires specific weights. |

Super Glue Drying Time Variations: How Long For Super Glue To Dry

Super glue, or cyanoacrylate adhesive, exhibits a range of drying times influenced by various factors. Understanding these variations is crucial for successful application in diverse scenarios, from small repairs to intricate assembly projects. Different brands and formulations of super glue react differently to environmental conditions and application methods.

Different types of super glue formulations have varying drying mechanisms, affecting the overall setting time. The precise chemical composition and additives play a key role in determining the speed and final strength of the bond. This detailed analysis will explore these factors in depth.

Comparison of Drying Times Across Brands and Types

Various super glue brands employ different formulations to achieve specific characteristics, including varying drying times. Some brands are known for faster curing times, while others offer stronger bonds that take longer to develop full strength. This difference often stems from subtle variations in the cyanoacrylate polymer and other components within the adhesive formula.

Differences in Drying Mechanisms

Super glue dries via a process of polymerization, where the liquid cyanoacrylate monomers combine to form a solid polymer network. Different formulas utilize variations in the monomers and additives, influencing the rate of this polymerization reaction. For instance, some formulas might incorporate catalysts or inhibitors to accelerate or slow down the curing process. The presence of these additives, and their specific concentrations, directly impact the polymerization rate and thus, the drying time.

Factors Influencing Drying Time for a Single Glue Type

Several factors influence the drying time even for the same super glue type. Ambient temperature significantly affects the polymerization process, with warmer temperatures accelerating the reaction. Humidity levels also play a role; high humidity can slow down the drying process due to moisture absorption by the adhesive. The thickness of the applied layer is another crucial factor; thicker layers require more time to dry completely. Additionally, the presence of contaminants or impurities on the bonding surfaces can affect the drying time.

Impact of Additives on Drying Time

Additives are frequently incorporated into super glue formulas to fine-tune various properties, including drying time. These additives can act as catalysts or inhibitors, affecting the speed of the polymerization reaction. For example, certain additives can accelerate the curing process, enabling quicker bonding, while others may slow down the reaction for more controlled curing. Understanding the role of these additives is essential for achieving desired drying times in specific applications.

Detailed Comparison of Drying Times Across Formulations, How long for super glue to dry

| Formulation | Typical Drying Time (seconds) | Chemical Composition (simplified) | Key Features |

|—|—|—|—|

| Type A (fast-drying) | 1-5 | Cyanoacrylate monomer with a catalyst | Rapid bonding, suitable for quick repairs |

| Type B (medium-drying) | 5-15 | Cyanoacrylate monomer with a moderate catalyst and plasticizers | Balanced bonding strength and drying time |

| Type C (slow-drying) | 15-60 | Cyanoacrylate monomer with an inhibitor and plasticizers | Stronger, more durable bond, suitable for heavy-duty applications |

Note: Drying times are approximate and can vary based on factors like temperature, humidity, and application thickness.

Troubleshooting Drying Issues

Super glue, while incredibly useful, can sometimes present challenges with its drying time. Understanding the potential problems and their causes is crucial for achieving successful bonding. This section details common issues, their origins, and effective solutions to ensure your projects proceed smoothly.

Proper drying is essential for a strong and lasting bond. Variations in drying time can stem from numerous factors, impacting the final outcome. Troubleshooting these issues can save time and materials, leading to more efficient and satisfactory results.

Common Super Glue Drying Problems

Various factors can disrupt the typical drying process. Understanding these factors is crucial for troubleshooting and achieving successful bonding.

- Incomplete Drying: The glue may appear dry to the touch but remain tacky underneath. This can lead to weak bonds and potential re-adhesion issues.

- Slow Drying: The glue may take significantly longer than anticipated to achieve a hard, permanent bond. This can stem from factors affecting the curing process.

- Uneven Drying: Areas of the bond might dry faster than others, resulting in an uneven surface or inconsistent bond strength.

- Incomplete Adhesion: The glue may not adhere properly to the surfaces, hindering the curing process. This can be caused by incompatible surface materials or inadequate surface preparation.

Potential Causes for Super Glue Not Drying Properly

Several factors can contribute to super glue not drying as expected. Identifying the cause is the first step in resolving the problem.

- Humidity: High humidity can slow the evaporation process, making the glue take longer to cure. This is a common culprit in humid environments.

- Temperature: Extremely high or low temperatures can also affect the curing rate. Extremes can disrupt the chemical reaction required for proper bonding.

- Contamination: Foreign substances, such as dust or oils, on the bonding surfaces can prevent proper adhesion, causing incomplete drying and weakening the bond.

- Incorrect Surface Preparation: Surfaces that are not properly cleaned or roughened can lead to incomplete adhesion and hinder the drying process. Cleanliness is paramount to ensuring a successful bond.

- Glue Quality: Using expired or low-quality super glue can result in inconsistent drying times and weaker bonds. Using the correct product type is essential.

Detailed Analysis of Unusually Long Drying Times

Unusually long drying times can be attributed to a combination of factors. Examining each possibility is essential to pinpoint the source of the issue.

- High Humidity: In humid environments, the air contains a significant amount of moisture. This moisture competes with the glue’s solvent, slowing the evaporation process and hindering proper curing.

- Low Temperature: Lower temperatures can reduce the rate at which the glue’s solvent evaporates, extending the drying time considerably.

- Thick Application: Applying a thick layer of super glue can hinder the evaporation process, increasing the drying time and potentially causing uneven drying.

- Contamination: Foreign substances on the surfaces can interfere with the glue’s chemical reaction, delaying the drying process.

Solutions for Preventing and Addressing Drying Problems

Implementing preventative measures and addressing existing issues can help ensure optimal drying times and strong bonds.

- Proper Surface Preparation: Ensure surfaces are clean, dry, and properly prepared for bonding. Use appropriate solvents and cleaning methods.

- Maintaining Optimal Conditions: Work in a controlled environment with moderate temperature and low humidity. Using a dehumidifier in high-humidity areas is an option.

- Using the Correct Glue: Select the appropriate type of super glue for your application. Using the correct product can minimize potential issues.

- Thin Application: Apply a thin, even layer of glue to promote consistent drying and avoid problems with uneven drying.

- Minimizing Exposure to Contamination: Work in a clean environment to avoid dust or other contaminants that can hinder the drying process.

Super Glue Drying Problems and Solutions

| Problem | Potential Cause | Solution |

|---|---|---|

| Incomplete Drying | High humidity, thick application, contamination | Reduce humidity, apply thin layers, ensure clean surfaces |

| Slow Drying | Low temperature, high humidity, contamination | Work in a controlled environment, use appropriate cleaning methods |

| Uneven Drying | Thick application, inconsistent temperature, uneven surface | Apply thin, even layers, ensure even temperature distribution |

| Incomplete Adhesion | Contamination, improper surface preparation, incorrect glue type | Clean surfaces thoroughly, use correct glue type, ensure proper surface preparation |

Applications and Drying Considerations

Super glue’s rapid drying time is a defining characteristic that makes it a versatile adhesive for a wide range of applications. Understanding the interplay between drying time and various factors, such as material types and surface conditions, is crucial for achieving successful bonding. Different projects necessitate different drying rates, impacting the overall outcome and precision of the work.

The speed at which super glue cures significantly affects its suitability for various applications. A quick-drying glue is ideal for situations where a rapid bond is needed, while a slower-drying variety allows for more precise placement and adjustments before the bond solidifies. The choice between these types depends heavily on the specific project and the materials being joined.

Impact of Material on Drying Time

Different materials react differently to super glue’s adhesive properties. The surface texture, porosity, and chemical composition of the materials influence the drying time. For instance, porous materials, like wood or certain fabrics, tend to absorb super glue more readily, leading to a longer drying time compared to smooth, non-porous surfaces like metal or plastic. This difference in absorption needs careful consideration during the application process.

Surface Type and Drying Time

The type of surface significantly affects the drying time of super glue. Smooth, non-porous surfaces generally exhibit faster drying times compared to rough, porous surfaces. This difference arises from the glue’s ability to spread and evaporate more easily on smooth surfaces. For example, gluing two pieces of polished glass will result in a much quicker drying time than gluing two pieces of wood. The unevenness and roughness of the surface can also influence the drying time, slowing down the evaporation process.

Examples of Applications Requiring Specific Drying Times

Various applications benefit from specific drying rates of super glue. Quick-drying super glue is ideal for tasks requiring rapid bonding, such as repairing broken jewelry or quickly securing small parts in model-making. Conversely, slower-drying super glue is preferred for applications requiring precise positioning and adjustments before the glue sets, like assembling intricate models or fixing delicate items.

Table Comparing Optimal Drying Times for Different Applications

| Application | Material | Glue Type | Drying Time Considerations |

|---|---|---|---|

| Jewelry Repair | Metal, Glass | Quick-drying | Rapid bonding for immediate repairs |

| Model Building | Plastic, Wood | Slow-drying | Precise placement and adjustments |

| Electronic Component Attachment | Circuit board, Metal | Quick-drying | Fast bond for small components |

| Fabric Repair | Cotton, Linen | Slow-drying | Controlled application for fabric integrity |

| Crafting | Cardboard, Paper | Variable | Depends on the specific craft and desired finish |

Visual Representation of Drying Process

Super glue, a ubiquitous adhesive, undergoes a fascinating transformation as it dries. Understanding this process, visually represented, aids in troubleshooting issues and maximizing its effectiveness. This section details the visual stages, chemical reactions, and physical state changes involved in the super glue drying process.

Visual Stages of Super Glue Drying

The drying process of super glue is characterized by distinct visual stages. These stages reflect the chemical reactions occurring within the glue and the subsequent changes in its physical properties. Observing these stages can provide insights into the drying time and overall performance of the adhesive.

- Initial State: The super glue, when first applied, appears as a clear, viscous liquid. Its consistency is akin to thick syrup, easily flowing and spreading over the surface. This liquid state is crucial for initial bonding. A photograph of this stage would show a clear, viscous substance.

- Early Stages of Polymerization: As the glue begins to dry, a slight haze or clouding may appear. This indicates the onset of polymerization, where the liquid monomer molecules begin to link together. This haze progressively increases, and the viscosity increases as well. A picture would show a slightly cloudy, thicker liquid.

- Intermediate Stage: The clouding becomes more pronounced, and the glue starts to become less viscous. The substance is now a semi-solid, with the majority of the liquid content absorbed or solidified. A photograph at this stage would show a distinctly opaque glue, exhibiting a sticky, but not completely solid, consistency.

- Final Stage: The glue transitions from a semi-solid to a hard, transparent solid. The polymerization is complete, and the glue has achieved its final, solid form. The bond is now fully formed. A photograph at this stage would show a clear, hard, and inflexible solid substance.

Chemical Reactions During Drying

The drying process of super glue involves a complex series of chemical reactions, primarily polymerization. This is a process where smaller molecules (monomers) combine to form larger molecules (polymers).

- Polymerization Initiation: The super glue contains a monomeric cyanoacrylate ester. In the presence of moisture, a catalyst (often moisture in the air) initiates the polymerization process. This catalyst triggers the reaction that creates chains of cyanoacrylate polymers. A diagram illustrating the initial monomer molecules could be helpful here.

- Polymerization Propagation: The monomers begin to link together in a chain-like fashion. This process continues until a substantial polymer network is formed. The illustration should show a schematic of the growing polymer chain, with the increasing number of monomers linked together.

- Polymerization Termination: As the polymer chains grow longer, they eventually become entangled and cross-linked, creating a three-dimensional network structure. The reaction concludes when the entire glue is transformed into a solid polymer. A photograph showcasing the network structure would be beneficial here.

Physical State Changes

The physical state of super glue transforms significantly throughout the drying process.

- Liquid to Semi-Solid Transition: The glue initially exists in a liquid state, with a high degree of fluidity. As the polymerization progresses, the liquid transforms into a semi-solid state, exhibiting a decrease in fluidity. The glue starts to become more viscous and less mobile. This transition is evident in the visual changes observed in the earlier stages.

- Semi-Solid to Solid Transition: The glue continues to solidify, eventually becoming a hard, solid material. The final stage is characterized by a completely formed, rigid, and non-flowing solid substance. This change is accompanied by a significant increase in the material’s strength and rigidity.

Essential FAQs

How long for super glue to dry – How does humidity affect super glue drying time?

Higher humidity slows down the drying process. Moisture in the air competes with the glue’s evaporation, leading to a longer drying time.

What are some common mistakes in measuring drying time?

Failing to account for temperature and humidity, using inconsistent application methods, or not accounting for surface area can lead to inaccurate measurements. Always maintain consistent conditions for reliable results.

Can different super glue brands have vastly different drying times?

Yes, variations in chemical composition and additives between brands can significantly affect drying times. Always consult the product specifications for accurate information.

Why might super glue not dry completely?

Insufficient pressure during application, improper surface preparation, or interference from external contaminants can prevent super glue from drying completely. Ensuring clean surfaces and proper pressure is crucial.